Manufacturing Facilities

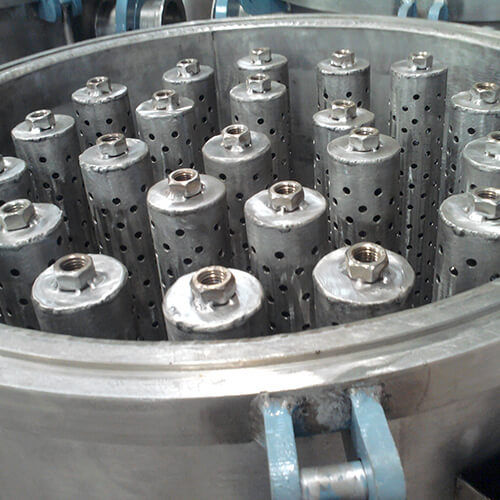

In Indias MIDC Talegaon, right next to General Motors, our company operates a state-of-the-art production plant with a covered shed of 15,000 square feet and an open area of roughly 35,000 square feet. The fabrication shed contains cutting-edge welding equipment, an overhead crane for material handling, and trained personnel who work in compliance with ASME code, Section VIII, Division I.

As a result of our continual research, we employ the most up-to-date CAD/CAM and other computer-aided technologies and have mastered designing and engineering. These are handled by our very skilled engineers, who have more than 25 years of experience in the field.

To keep our team up to date on the most recent developments in the processing industry, we do market research. Our knowledgeable and experienced professionals can handle P & ID, structural layouts, and all particular piping layouts in accordance with site specifications while designing and supplying oil plants.

Our Team

In our company, we work as a happy and driven family that turns work into the pursuit of excellence in a positive working environment. We have a team of specialists who are exceptionally skilled at building high-performing processing facilities and machinery for food oil, alcohol, and biofuels. Our team of production engineers and technicians brings a wide range of processing machines to the market thanks to their extensive knowledge, sharp minds, and unwavering work ethic. To make sure the equipment complies with the international standard, the quality auditors rigorously oversee the entire procedure and inspect each stage of production.

The sales and marketing teams are glad to help clients with their many product-related questions because they are informed about market dynamics. In addition, we have a dedicated team of project managers and other competent staff members who effectively finish turnkey projects and offer effective post-sale services, such as erection and commissioning, as well as on-site support, at affordable pricing. Our workplace treats every team member with respect, and the culture organically motivates all employees. In order to keep our force abreast of the most recent developments and to help them gain new skill sets and a higher level of knowledge, we also provide timely and appropriate training.

Turnkey Projects

For edible oil refining plants with capacities ranging from 10 tpd to 500 tpd, we manufacture and offer complete projects. Up until commissioning, we help clients with design ideas, machinery layouts, and utility layouts. We Offer Full-Service Packing And Processing Solutions For Adding Value To By-Products For Edible Oil Refining.

Our Mission

Thanks to methodological approach that we at Brissun has implemented over the all these operational years, the company has emerged as one of Indias leading solution providers for processing industries, plants, heat exchangers, and distillation plants. We have mastered the method of processing various types of oils. Our engineers works hard to offer customers the best intelligent solutions. Our specially designed process will give you the best heat recovery, the least amount of power consumption, and the least amount of thermic fluid consumption whether you are processing sunflower oil, soybean oil, palm oil, or cottonseed oil.

Our Vision

The basis of our vision is our dedication to building a business that collaborates effectively with its three partner groups customers, employees, and suppliers. Further, we aim to be our clients preferred partner by knowing their needs better than our competitors. Our vision also includes the following:

- Providing them with the most effective, inexpensive, and quick solutions possible

- Testing our products continuously

- The best technical support

- Customer service in the industry

|

BRISSUN TECHNOLOGIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese